- Company

- The product you're looking for

We will respond to the best quality and price.

R&D

-

- 2017

- 09

- Changed name as ‘Sungwon Ind. R&D center’

-

- 2014

- 01

- Newly established R&D center in new location

-

- 2008

- 12

- Establish R&D Center

- Manufacturing

- Quality

- Design

- Logistics

R&D Center member

Project

- Development of compressor housing bolt using Pre-heat Treatment Steel.

Purpose

-

Improve quality & cost reduction with high-strength material.

-

VE(Value Engineering)

- - Eliminate heat treatment process to have cost reduction.

- - Discovering up-to-date technique and developing methods to secure competitiveness among fastener industrial.

-

Zero Defect

- - NG parameter such as scale or bending are eliminated by omitting heat treatment process.

-

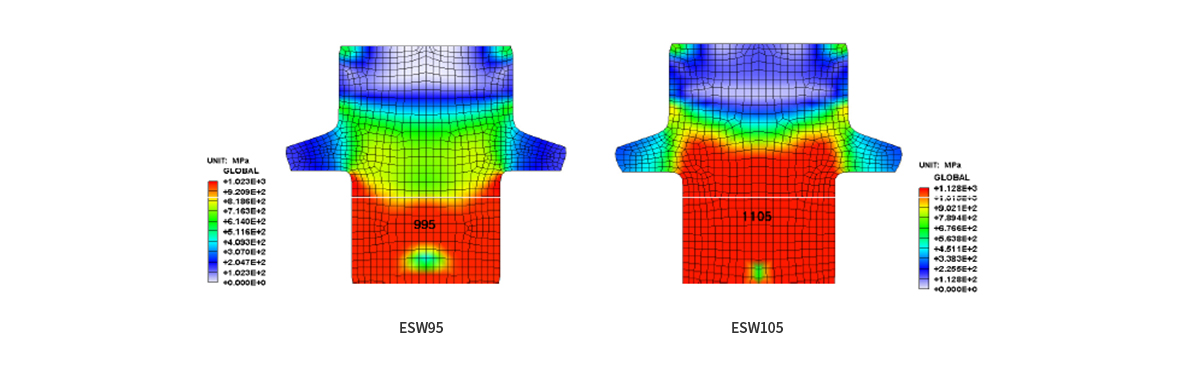

R&D result

-

Developed the forging method to minimize the forging stress

Designed tooling for withstand high forging pressure with high tension material.

-

VE(Value Engineering)

-

-

Bolt Delayed fracture failure test.

-

Bolt Delayed fracture failure test. Test item Bolting torque (N.m) Sample amount (ea) Duration time (hrs) Test result ESW95 260 26 96 Pass ESW100 260 26 96 Pass ESW105 260 26 96 1ea NG ESW110 260 26 96 9ea NG ESW115 260 26 96 13ea NG

-

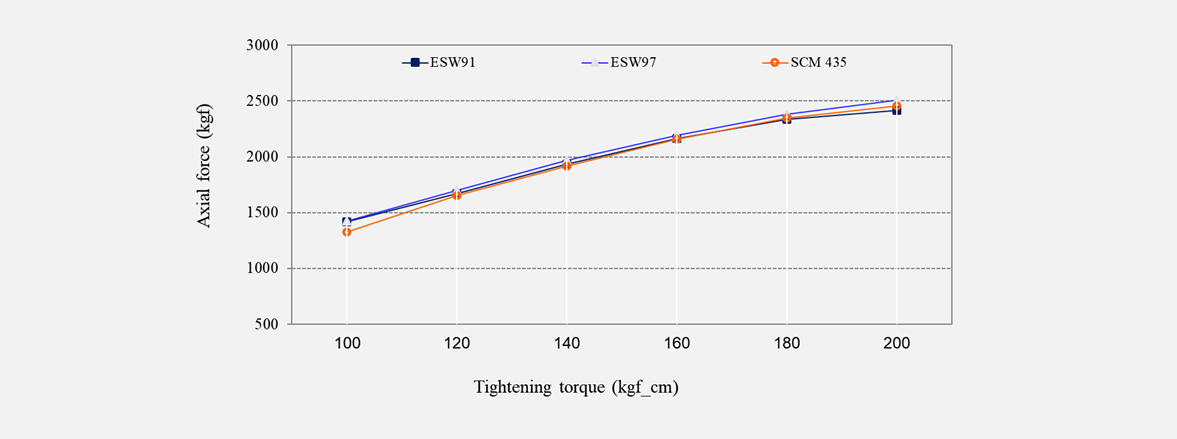

Bolt Axial Force Test

-

-

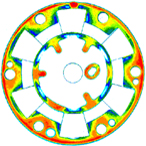

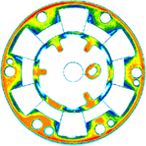

Compressor assembly inner load test

-

Compressor assembly inner load test SCM435 #1 SCM435 #2 ESW91 #1 ESW91 #2 Rear head side

Load(N) 121530 122567 114534 122611

-

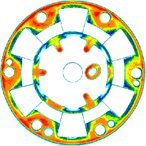

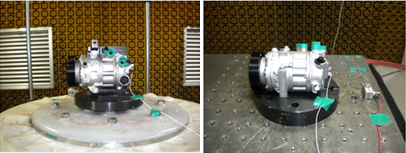

Compressor assembly DV test

-

Compressor assembly DV test Before durability After durability Differetial (%) 800rpm Capa.(kcal/h) 3633 3607 0.7% HP(HP) 2.00 1.94 3.1% COP 2.84 2.91 -2.3% Td(℃) 86 88 -1.7%

-

Results

-

- 7.3% cost down on piece price

- Zero Defect in leak rate on compressor assembly.